cooling tower parts & Functions

35000.0 INR/Number

தயாரிப்பு விவரங்கள்:

- பயன்பாடு industrial

- பொருள்

- தயாரிப்பு வகை cooling tower parts & Functions

- விண்ணப்பம் cooling tower

- உத்தரவாதத்தை yes

- மேலும் பார்க்க கிளிக் செய்யவும்

X

விலை மற்றும் அளவு

- 100

தயாரிப்பு விவரக்குறிப்புகள்

- cooling tower

- cooling tower parts & Functions

- yes

- industrial

வர்த்தகத் தகவல்கள்

- மாதத்திற்கு

- வாரம்

தயாரிப்பு விளக்கம்

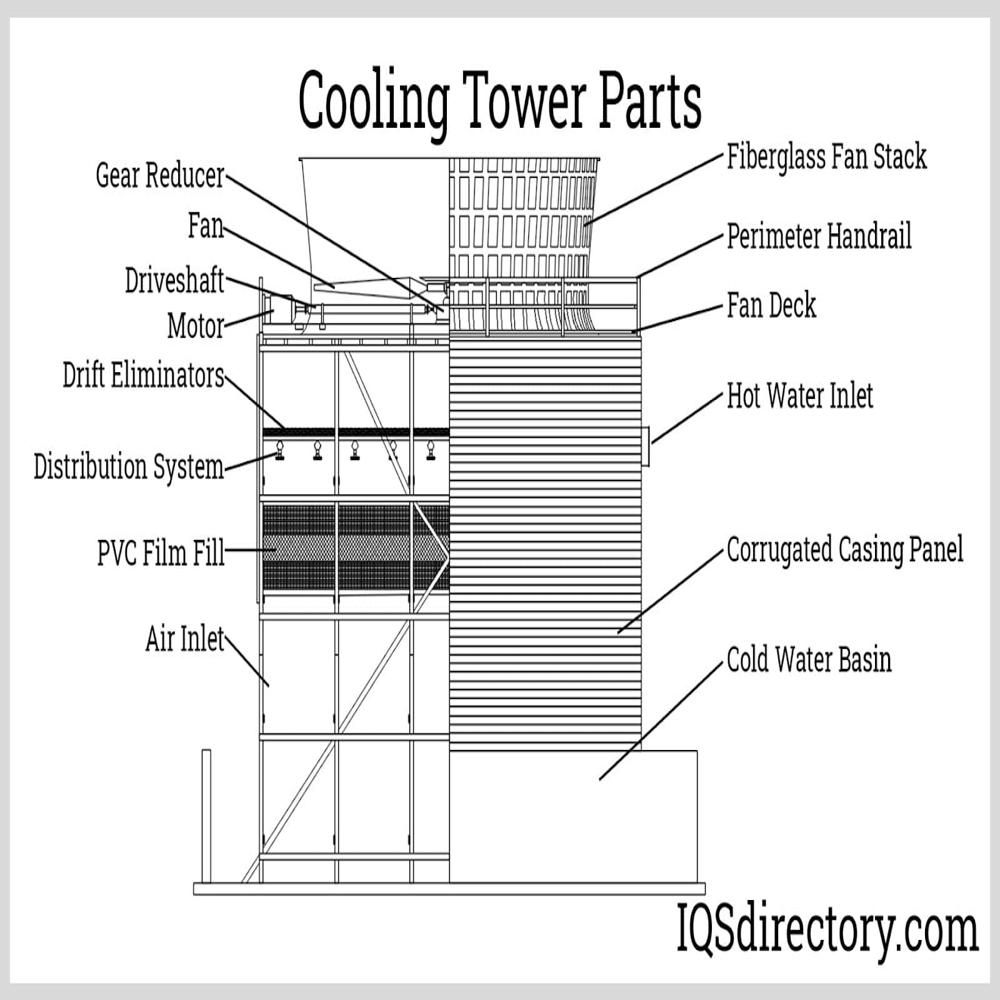

Cooling towers, essential for heat dissipation, consist of key parts likebasins, fills, nozzles, and drift eliminators, each playing a crucial role in the cooling process, and can vary significantly in size and shape.

Key Parts and Functions:

- Cooling Tower Basin:

- Collection Basin:Located at the bottom, it collects cooled water and directs it to the pump suction line or sump.

- Distribution Basin:An elevated, shallow-type basin that distributes hot water to the tower via holes in the basin floor.

- Cold Water Basin:Serves as storage for cold water and provides the main structure and foundation for the cooling tower.

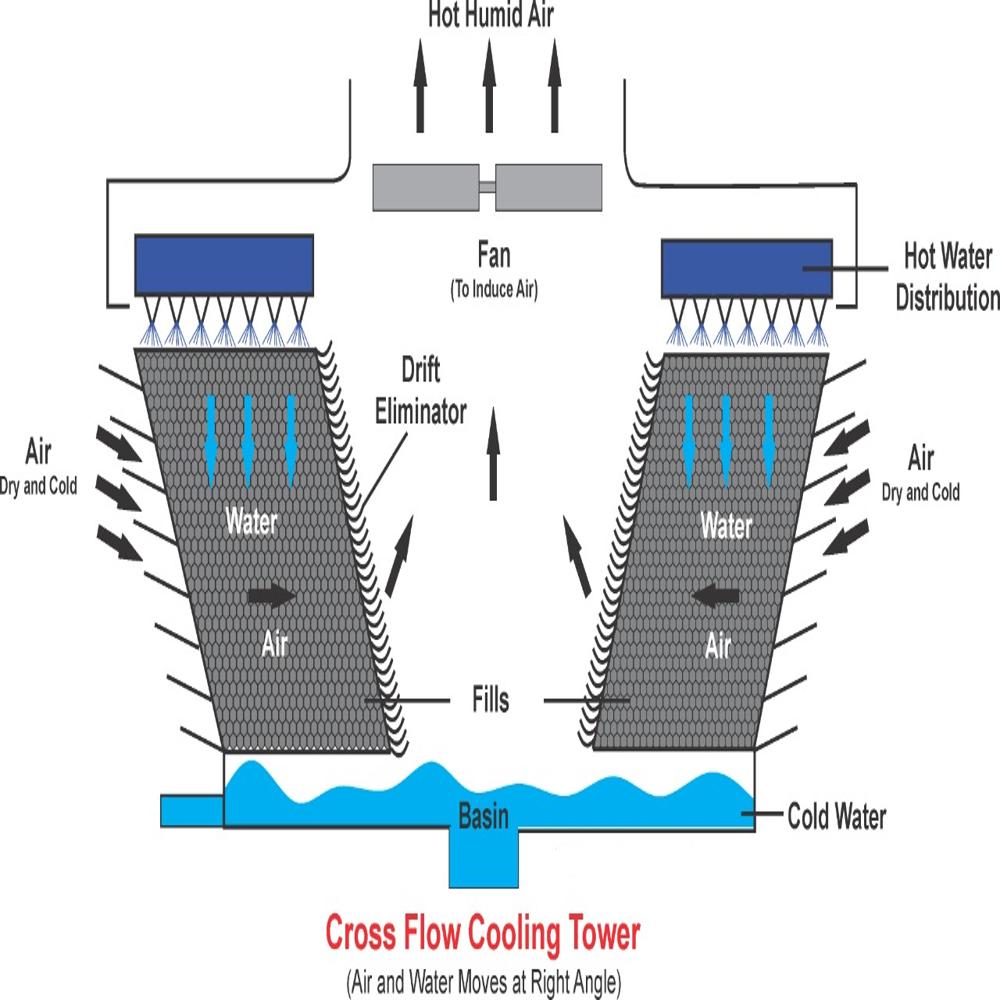

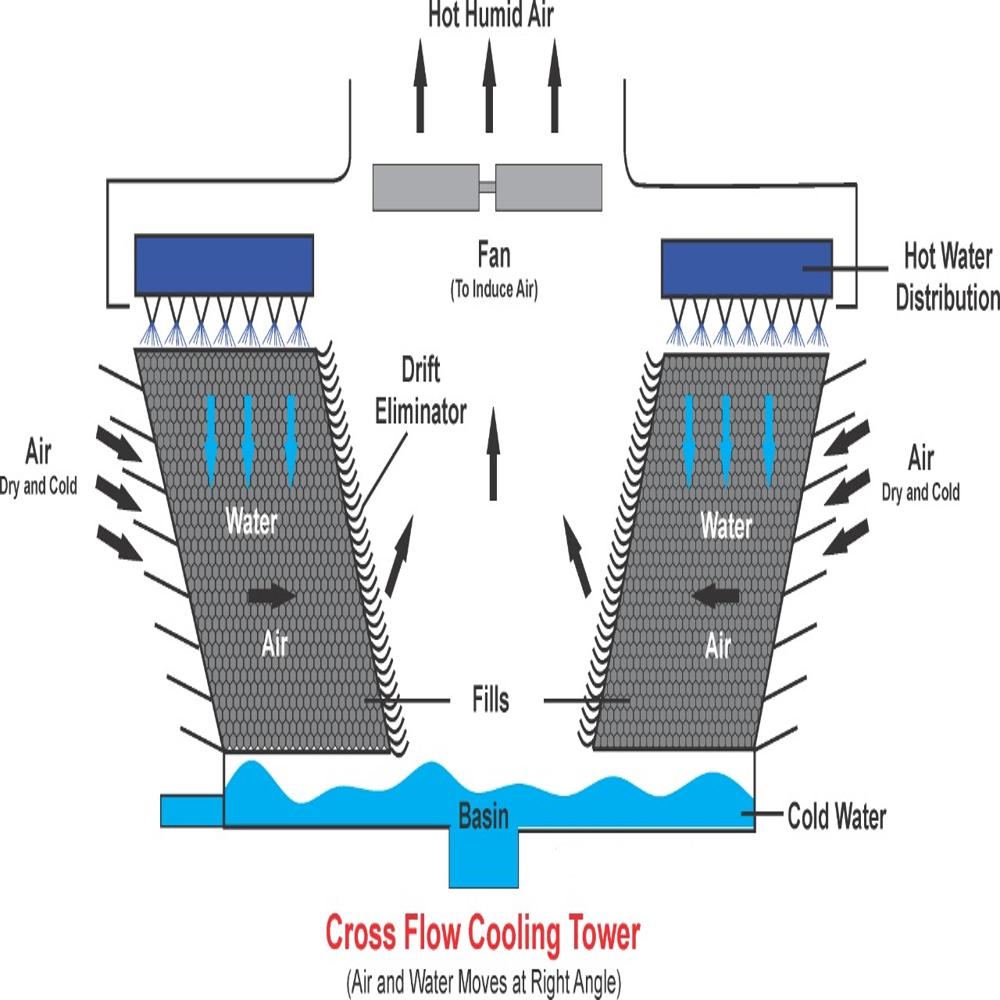

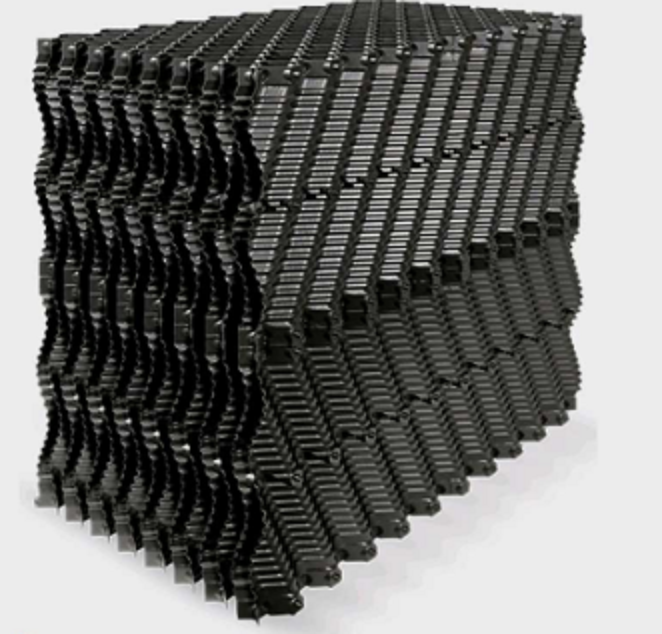

- Cooling Tower Fills (Heat Exchange Surface):

- These are the surfaces where water and air interact, facilitating heat exchange.

- They are designed to maximize contact between air and water for efficient heat dissipation.

- Cooling Tower Nozzles:

- These are affixed to the hot water pipes and spray water onto the fills.

- They contribute to the enhancement of the cooling effect by dispersing water across a broad area.

- Cooling Tower Drift Eliminator:

- These capture large water droplets from the air stream, preventing them from being carried away.

- Other Important Parts:

- Fans:Driven by motors, they circulate air through the tower to promote evaporation and heat transfer.

- Gearbox:Slows down the rotational speed from the motor to the fan.

- Driveshafts:Connect the motor and gearbox, transmitting power.

- Air Intake Louver:Blocks water splash-out, noise, and debris.

- Piping:Distributes water within the cooling tower.

- Float Valve:Maintains the right water levels inside the cooling tower.

Length and Width:

- Cooling towers come in various sizes, from small roof-top units to large hyperboloid structures.

- Hyperboloid towers can be up to 200 meters (660 ft) tall and 100 meters (330 ft) in diameter.

- Rectangular structures can be over 40 meters (130 ft) tall and 80 meters (260 ft) long.

- A cooling tower example is 21.65 m wide 36.9 m long 15.24m high.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

கைபேசி number

Email