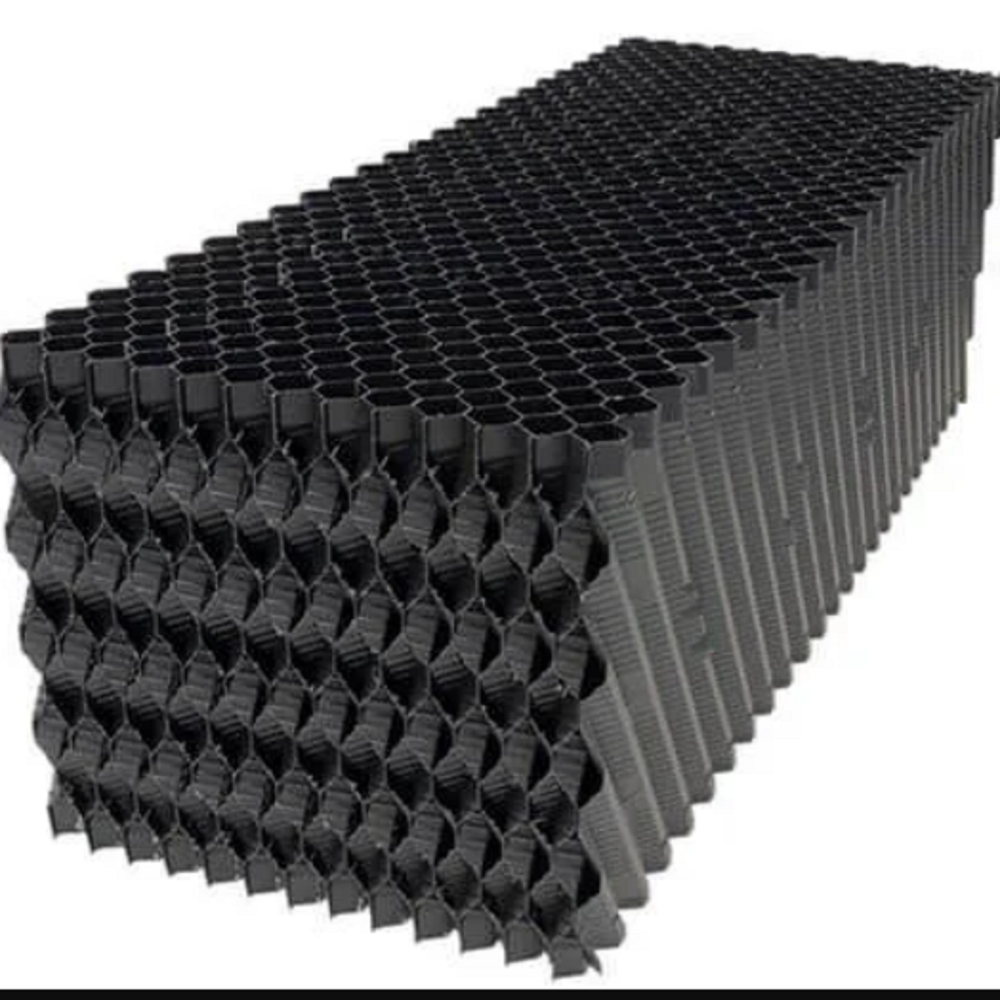

PVC Drift eliminators

Product Details:

- Width 300 Millimeter (mm)

- Length 600 Millimeter (mm)

- Color BLUE

- Material PVC

- Usage Cooling Tower

- Product Type PVC Fills

- Height 150 Millimeter (mm)

- Click to View more

PVC Drift eliminators Price And Quantity

- 650.0 INR/Number

- 100 Number

PVC Drift eliminators Product Specifications

- PVC

- BLUE

- Cooling Tower

- PVC Fills

- 150 Millimeter (mm)

- 300 Millimeter (mm)

- 600 Millimeter (mm)

- PVC Fills

PVC Drift eliminators Trade Information

- Cash in Advance (CID)

- 500 Number Per Day

- 1 Week

- All India

Product Description

PVC drift eliminators arecomponents used in cooling towers and similar systems to capture and redirect water droplets that escape with the exhaust air, minimizing water loss and chemical discharge.

Here's a more detailed explanation:

- Function:

Drift eliminators, made from polyvinyl chloride (PVC), are designed to reduce the amount of water droplets that escape from a cooling tower or evaporative condenser.

- Installation:

They are installed on the discharge side of the tower, either above the heat transfer surface or vertically.

- Benefits:

- Water Conservation:By capturing and returning water droplets, drift eliminators help conserve water and reduce operational costs.

- Environmental Protection:They minimize the discharge of chemicals and other impurities into the environment.

- Reduced Corrosion:By preventing the escape of water droplets, they help prevent corrosion of pipes and other systems.

- Reduced Bacterial Dispersion:They help prevent the dispersion of harmful bacteria.

- Types:

- Cellular Drift Eliminators:These are constructed from overlapping PVC sheets, creating a curved shape with multiple impact zones to capture water droplets.

- Other Types:There are also other types of drift eliminators, such as those with a "CD-100" or "CD-S130" design, which are designed for different types of cooling tower applications.

- Materials:

PVC is a common and cost-effective material for drift eliminators due to its resistance to corrosion and chemical degradation.

- Maintenance:

Drift eliminators are designed to be easily removed for inspection and maintenance of the water distribution system.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+