Paharpur cooling tower fills

Product Details:

- Usage Cooling tower

- Color BLACK

- Material PVC

- Product Type Paharpur Cooling Tower Fills

- Type Paharpur Cooling Tower Fills

- Click to View more

Paharpur cooling tower fills Price And Quantity

- 850.0 INR/Number

- 100 Number

Paharpur cooling tower fills Product Specifications

- PVC

- Paharpur Cooling Tower Fills

- Cooling tower

- BLACK

- Paharpur Cooling Tower Fills

Paharpur cooling tower fills Trade Information

- Cash in Advance (CID)

- 300 Number Per Week

- 2 Week

- All India

Product Description

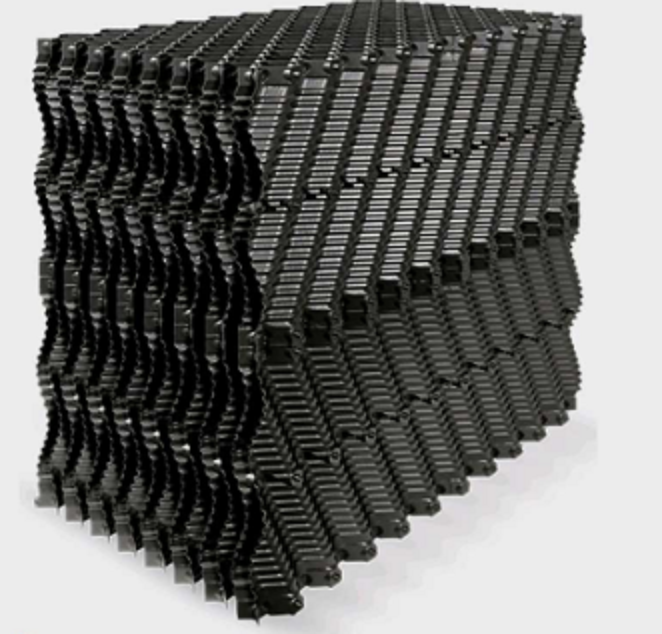

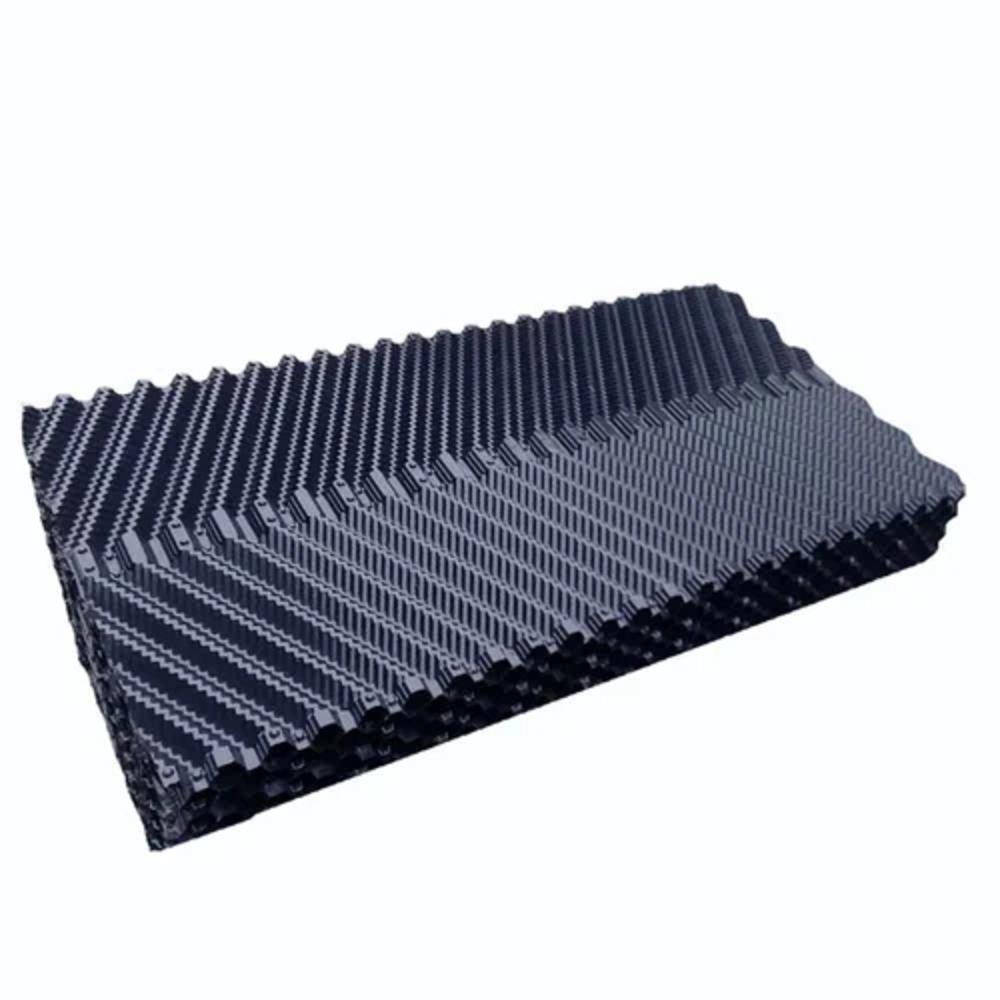

Paharpur cooling tower fills, often made of PVC, aredesigned to maximize surface area contact between water and air for efficient heat exchange, with options like film-type and splash-type fills available, and are known for their corrosion resistance and ability to withstand high temperatures.

Here's a more detailed breakdown of Paharpur cooling tower fills:

Types of Fills:

- Film-type:

These fills, often vacuum-formed PVC, have a chevron pattern to increase cooling rates and are highly adaptable to various tower configurations.

- They are corrosion-resistant, impervious to chemical attack, and can withstand temperatures up to 55C.

- Splash-type:

These fills are designed for applications where water contamination is common or in dusty factory environments.

- Wood fill:

Paharpur also provides wood fill cooling solutions.

- Cross-corrugated:

Paharpur's cross-corrugated fill design maximizes surface area contact and contact time between air and water, while also maintaining low resistance to airflow.

- Sigma type:

Paharpur also supplies sigma type fills suitable for various cooling tower brands.

Key Features and Benefits:

- Corrosion Resistance:

Paharpur fills are designed to be highly resistant to corrosion, ensuring long-term performance and durability.

- High Heat Transfer:

The design of the fills, especially the cross-corrugated and film-type options, maximizes surface area contact for efficient heat transfer.

- Low Pressure Drop:

Paharpur fills are designed to minimize resistance to airflow, reducing the amount of energy required to operate the cooling tower.

- Adaptability:

Paharpur offers a variety of fill types and configurations to suit different cooling tower designs and applications.

- Uniform Water Distribution:

Paharpur uses spiral spray nozzles to ensure uniform distribution of water over the fill, maximizing cooling efficiency.

Applications:

- Paharpur cooling tower fills are used in a wide range of applications, including HVAC, automotive, and domestic water use.

- They are also used in industrial applications such as power plants, fertilizer plants, petrochemical complexes, and petroleum refineries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+